Learn about metal Brazing

Are you looking to take your skills to the next level? Do you want to be able to join metal pieces together with precision and strength, without the big expense of buying a welder or having a dedicated space? Do you also want the join to be seamless?

If so, then learning to braze metal is the essential skill that you need to master.

Brazing is a versatile metal joining process that uses a filler metal with a lower melting point than the base metals being joined, allowing for strong, durable, and virtually invisible joints. With brazing, you can join a wide range of metals, from copper and aluminum to steel and titanium, making it an invaluable technique for any metalworker or fabricator.

Whether you're working on a complex project, a custom piece of jewellery, or simply trying to repair a broken part, brazing can help you achieve professional-grade results with minimal effort. The best part? It's not as intimidating as it may seem.

In this blog post, we'll be exploring the world of metal brazing, covering everything from the basics of the process to its limits. We'll also be sharing useful tips and information that might help you get started or just answer some of your questions.

You can learn Brazing Skills as part of our online course programme!

TREAT YOURSELF TO 20% OFF WITH CODE: BRAZE20

(Course normally £69.00)

Discover more about our online course

There are several types of metal brazing processes the two main processes which we will discuss in this post are;

Torch Brazing using an Oxygen and Acetelyn / Propane torch

Torch Brazing using MAPP Gas from disposable bottles.

The two methods mentioned earlier are generally the most commonly available techniques for metal brazing. Opting for the second option may be the most cost-effective approach, yet it could also present some constraints, potentially making it unsuitable for certain scenarios mainly to do with the size of the piece of metal you plan to join.

Let's begin by examining the various pros and cons associated with the process of metal brazing.

Pros

Strong joints: Brazed joints are strong and can withstand high temperatures and stresses.

Corrosion resistance: Brazed joints are resistant to corrosion and can withstand harsh environments.

Versatility: Metal brazing can be used on a wide range of materials, including copper, aluminum, steel, and titanium.

Aesthetics: Brazed joints can be virtually invisible, making them ideal for applications where appearance is important.

Cons

Limited thickness: Metal brazing is typically limited to joining thin sections of metal, as thicker sections can be difficult to heat evenly.

Material limitations: Some metals, such as titanium and aluminum, can be difficult to braze due to their high reactivity or tendency to form brittle oxides.

Finishing: Cleaning up and Finishing the joints can be time consuming.

Why would you braze metal:

Metal brazing is commonly used in various industries and is a convenient way to get a decorative finish to a joint. It can be used within the Aerospace & Automotive industry for components and engine parts such as turbochargers and exhaust system. It is also used in construction for joining pipes and plumbing systems.

It would be used in the furniture making industry to get a decorative join in metalwork or this would be especially helpful when building furniture from metal tube. You also use a brazing process when using Brass in furniture projects.

Brazing is also used in the Bicycle building industry for the assembly of bike frames.

What gases to use for Brazing?

Using the correct gas for metal brazing makes a difference; one option discussed is expensive the other option is much cheaper we written about both to help you make up your mind about what is the most suitable method.

A different chemical combination of gasses help produce a really hot flame suitable for brazing. The classic burning gasses are Oxygen, Acetylene or Propane - mixed in different combinations. By using a professional brazing torch set up you can mix these gasses to create a hot flame suitable for metal brazing or cutting.

The problem with this classic more professional method of brazing; is that it’s expensive to buy the equipment (gas bottles, regulators, hoses and torches) more dangerous and requires more skill to fine tune flame. Therefore; not really viable for a recreational user - unless you are planning to make brazing your go to method for joining metal.

The burning tempuratures of Gases below:

Acetylene when used in combination with Oxygen has a higher flame temperature 3160 °C

Oxygen and Propane mixture can create flames of 2896 °C

Brazing Gases available from HobbyWeld

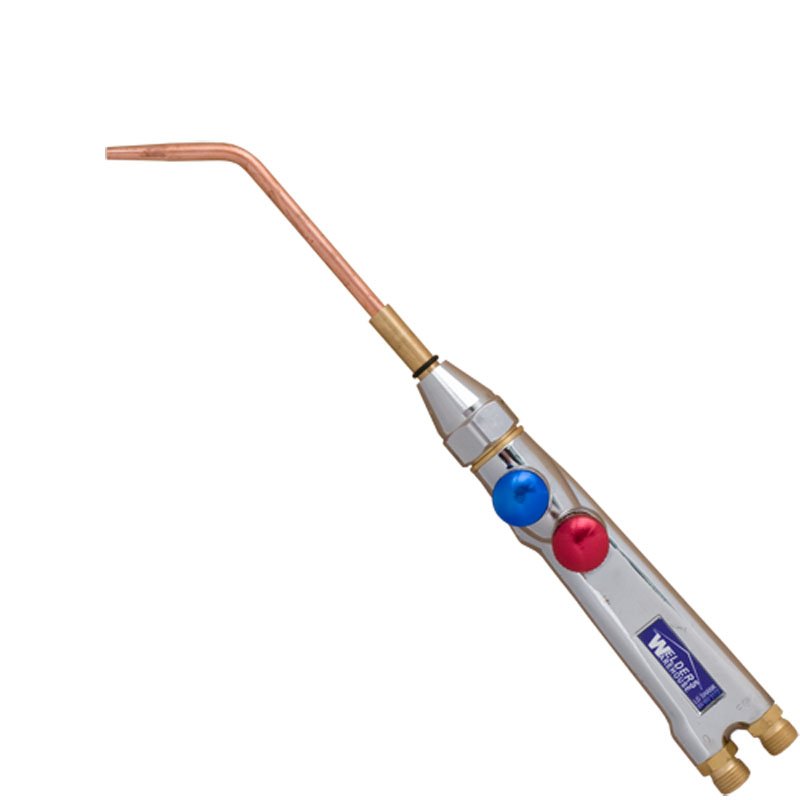

Gas Brazing Torch. Type 5 Shank with small nozzel

Acetylene and Oxygen Regulators for Metal Brazing

Techical information: Using Oxygen & Acetylene gases with a professional brazing torch and regulator set up. Will help mix these two gasses together into a focused flame. As Acetylene is a lighter and more fluid gas it mixes with oxygen well. A professional brazing torch (TYPE 5 Shank) can adjust the Flow of the two gases and concentrate the flame. Creating a very higher temperature that burns quickly (thanks to the oxygen). Therefore providing the operator with the ability to heat up metal quickly. Used in larger quantities it can used to cut metal.

Propane and Oxygen mixtures can also be used to create a hot flame but a larger nozzle is required on the brazing torch to help mix the propane and oxygen together. This is because propane is a heavier, slightly harder gas to mix.

MAPP Gas for Brazing:

The other gas used for creating hot flames is MAPP Gas and it is a much more attractive option due to:

Low cost of operating and starting.

Ability to safely use

Simplicity to use

MAPP Gas - is really just a trademarked name that belongs to The Linde Group (who own BOC) - for a fuel gas based on a stabilised mixture of methylacetylene (propyne), propadiene and propane. It can create a flame with a temperature of 2925 °C.

MAPP Gas burns at 2925 °C

Propane on it’s own can burn at 1,980 °C

The reason MAPP Gas can create this temperate flame from one disposable bottle, is a result of the torches nozzle design. Which is generally larger in size and allows for the successful mixing of MAPP gasses into a vortex, as they come out of the bottle under pressure. This vortex helps create a very hot flame.

Limits of MAPP Gas

Given that the flame is limited in focus and heat the MAPP Gas and Handheld torch option is limiting. The limit is generally to do with;

the size of the component you want to braze

The Wall Thickness of the part.

We have found by using MAPP Gas you are limited to using material with a Wall Thickness 1 to 1.5mm. The reason for this is because you are required to heat the metal up to a red hot heat. The thicker the material the harder it is to achieve level of temperature in the material.

The other limiting factor is the the size of the component, the larger the piece or component you are trying to braze the more heat will be required to make it reach brazing temperature. As when piece of metal starts to get hot the heat starts to transfer through the piece of metal creating disparity in temperate of the join to be brazed. It can take an excessive time or impossible to braze large metal joints in this way.

This is why we recommend brazing on small components only.

How to Braze Mild Steel using MAPP Gas:

Below are a few few tips to help you learn how to get started with brazing, saying that, it does not replace tuition. The Weld Space provides courses that will help you learn to braze Mild Steel tube to Mild Steel tube our Studio Stool Course. The Course teaches you about metal brazing in order to join Mild Steel tube together. It is a day long course that provides you with the best example of when you might braze metal using Mapp Gas.

Watch our Youtube Video and see how you can Braze with Mapp Gas.

Learn to Braze

Join our one-day course and learn about brazing mild steel tube. Perfect for bike frames or furniture or small jobs.

£136.00 Per person | Dates available | Book online

Some key equipment to buy:

Brazing Flux - Click here to Buy

Brazing Rods for Mild Steel - Click here to buy

Mapp Gas Bottles - Click here to buy

Brazing Torch - Click here to buy

Some Useful safety Equipment:

Heat Protective Gloves

A mask for fumes - static extraction is ok.

Eye Protect (Shade 5 Goggles) - if using Oxygen/acetylene Torch set up.

How to Braze:

Make sure your joint is clean and free from any dirt or grime before you start brazing.

You need to create a paste using the flux. You do this by adding dribbles of water to the flux powder and then painting it on your joint - you can never have enough flux at this point so make sure it goes into every nook and cranny.

You will then use your torch to evenly heat the joint to be brazed. You want to make sure it's evenly heated across all areas of the joint this will take some time and requires a lot of movement of the torch and flame. (for component's lying on a heavy metal bench it might be advisable to try and raise it up or use heat resistant brick or matt. Sometimes the flames heat transfers into the metal bench you're using)

Once you have got the joint up to a cherry red colour you then start dipping your filler rods into the joint at this point it should be liquid and it uses capillary action to transfer the filler metal into the joint.

You will need to keep the flame and the piece of metal hot whilst doing this and repeat the process if necessary. Moving the torch around is really important. As getting the piece too hard can be detrimental.

When you are satisfied that the joint is successfully braised remove the heat and let it cool.

The flux cools to a glass like substance which can be removed with hot water. Boil the kettle, have a cup of tea and then pour the remaining water over the joint.

This should remove a lot of flux you'll then have to inspect the joint and see how it has bonded to the metal.

Cleaning up the joint requires some effort generally using emery cloth or a file.

Brazing using MAPP Gas

Brazing a join using MAPP Gas

Finished joins brazed using MAPP Gas

Discover our Online Welding Programme

Over 50 lesson introducing you to the Basics of Welding, brazing and metalwork.

Only £89.00

What is Capillary action:

Capillary action is the phenomenon where a liquid flows through a narrow space or tube without the need for any external pressure or pump. This occurs when the adhesive forces between the liquid and the surrounding material are greater than the cohesive forces within the liquid itself.

In other words, capillary action is the ability of a liquid to flow through a small space or tube against gravity due to the attraction between the liquid molecules and the molecules of the surrounding material. This is different from forced flow, where a pressure difference is required to move the liquid.

How to Braze Brass to Brass:

If you are planning to braze Brass to Brass mainly for decorative reasons. It is a similar process to the above albeit you will need to use Silver Solder as a filler rod to achieve this bond. Silver solder is very expensive but can be bought online, Silver solder melts at around 700° and brass melts around 900° therefore the silver solder melts well before the brass will melt. This is the key to the brazing process.

Example of Brazing Brass to Brass with Silver Solder.

Seamless Silver Solder Brass joint from a bespoke piece of furniture made by RichCraft Furniture.

Left over Flux for from Brazing Brass.