Different Types of Aluminimum

Embarking on a welding and fabrication journey opens up a world of possibilities, aluminium will start to emerge as a potential material along the way. In this blog post, we delve into the compelling reasons behind the use of aluminium, exploring its benefits and potential drawbacks, while also shedding light on how you might weld this versatile material.

Aluminum, an alloy renowned for its lightweight yet robust nature, it hold a pivotal role in various industrial and creative sector applications. As might have guessed, aluminum is made up of a diverse spectrum of composits, each tailored to specific application. From cost-effective variants to high end mixes, there will be something suitable for your project.

Our mission in this blog post, is to demystify the use of aluminum in fabrication, empowering beginners to feel more confident using it or simply to save you time and effort learning the reasons why you shouldn’t use it.

What is Aluminium?

Aluminum is a versatile and lightweight metal that is widely used in various industries such as construction, transportation, electronics, and furniture. It has excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity, making it an ideal material for a wide range of applications. People often use aluminium in projects, for its malleability and ease of fabrication. It can be easily shaped, cut using basic workshop tools and machinery such as Routers and Jigsaws (with the right blades).

What items are made from Aluminum?

Aluminium is found in many of today's products, it frequently features in engines and outdoor furniture. Its prevalence stems from its lightweight nature and exceptional resistance to corrosion. These attributes render aluminum ideal for Car or Motorcycle Engines, outside furniture and items in the Marine Industry. Aluminium can endure harsh environmental conditions as it will not rust. Due to it’s lightweight nature it is used most commonly in the construction of Airplane.

Advantages of aluminium:

Aluminum is a popular material since it is easy to machine, being a soft material, allowing aluminum to be easily bent, cut and shaped without the need for heavy duty tools.

Finished in a RAW state aluminium can provide a nice surface finish.

It is light weight material.

Conducts heat very well.

Is recyclable.

Disadvantages:

Aluminium is it is an expensive material to buy.

It can be tricky to weld and generally requiring the use of a TIG Welder

It can be brittle when welded.

Conducts heat very well.

A modern example of Furniture made from Aluminium is this Bespoke Aluminimum Dining table made by Richard Evans from RichCraft Furniture.

Aluminium dinning table created by Richard Evans at RichCraft Furniture

Different Types Of Aluminium:

There are various types of Aluminum which all serve different purpose. The various qualities of aluminum are used for different purposes. Different Aluminum alloys are classified by a four digit number, with each of the first digit relating to alloys with similar properties. Common examples of aluminium alloys include for Example;

1000 Series: Typically found in thin sheet aluminium which is usually reserved for decorative or non load bearing applications.

5000 Series: Typically used in solid forms of aluminium like solid bar. It offers good weldability, corrosion resistance, and moderate strength. This series of alloys are widely used in marine applications, such as boat hulls as well as automotive components and structural materials

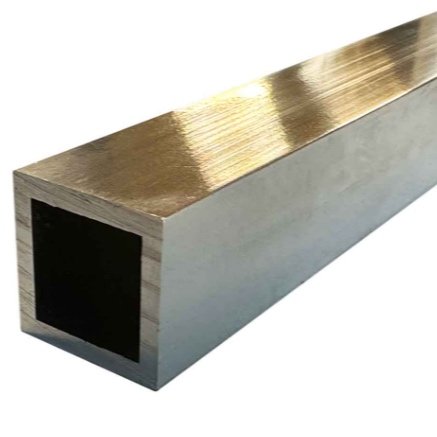

6000 Series: Commonly used as structural aluminium, this material is typically used in hollow box or hollow round section aluminium for structural applications. Due to its excellent extrudability, This series of alloys are often used in architectural and structural applications such as: window frames, door frames, and curtain walls.

The make up of different grades of aluminium is all relevant to what you need it for. In works places it is not uncommon for Metallurgist to be employed to calculate the mixtures or grades. For some unsure, what a Metallurgist is; they are professionals who specializes in the study and manipulation of metals and alloys.

Aluminium Material Library:

Below is a list of the different types of sections you can buy of Aluminium. There are a number of different suppliers in the UK. Locally here in Plymouth we use:

Holme Dodsworth - The Weld Spaces order our materials from Holme Dodsworth since they provide full lengths of aluminium which are typically up to 5 metres in length. Holme Dodsworth Metals is one of the UK's leading Non Ferrous stockists. They have other UK branches around the Country.

Other suppliers are:

Aluminium Warehouse - Are a specialists supplier in metals from aluminium, stainless steel, mild steel (ERW), brass and copper. They provide a cutting service for precise and accurate cut to size metal. We’ve found delivery tends to take a little longer from these guys but they have a excellent range and great website.

Metals 4 U - The biggest online retail metal supplier in the UK. Whether you are a keen hobbyist, tradesperson or contractor, they can help you find all the materials you need. They will sell you a 30cm length or many meters. They also offer a cutting service.

Aluminium Angle

Aluminium CheckerPlate

Aluminium Round Bar

Aluminium Square Box Section

Rectangular Box Section

Aluminium Flat Bar

Aluminium Sheet Material

Aluminium T-Bar

Aluminum Z-Section

U-Channel

Aluminum Plate

Aluminium Solid Square Bar

Aluminium Round Tube

How do you Weld Aluminium:

The caveat for using aluminum is that it requires different welding techniques to join it compared to materials like mild steel. Aluminum is generally welded using tungsten inert gas Welding Methods. (TIG welding) using an alternating current. These machines are commonly called AC/DC TIG Welding.

Tungsten inert gas welding (TIG welding) is a welding process that uses electricity to melt and join pieces of metal. Its popularity has grown which is largely due to its versatility, cleanliness and minimal finishing requirement. It’s suitability for welding so many different metals.

Whenever aluminum is welded using the TIG welding process, Alternating Current is used.

Alternating current (AC), changes the electrical current’s direction and makes the positive electricity bounce back and forth from the electrode to the work piece. This is helpful as when welding aluminium it can be tricky to break through the very thin but strong oxide layer. This very thin layer only melts at approximately 2015 degrees Celsius, but aluminum itself melts at around 650 degrees. This means that the aluminum would melt while the oxide layer was being melted, making welding impossible. The oxide layer needs to be destroyed in order for fusion to occur.

AC/DC TIG Welding Machines are available from many different suppliers. We use machines supplied by R-tech.

There R-Tech TIG Welder AC/DC 160 Amp 240v is sufficient for my aluminium jobs albeit it might struggle on very thick plate for sheet without pre-heating.

AC/DC TIG Welders are generally more expensive than DC TIG welders due to the additional electronic components within them. Machines like the one shown have any useful features found in high-end machines and prices start from £999.00.

Remember, when welding Aluminium you will need to use an Aluminium Filler Rod. Unless welding pure Aluminium product make sure your welding rods contain a element of magnesium as this will make it more sturdy.

Learn How to Weld Aluminium with The Weld Space.

We have a couple of options to suit most beginners.

Join our TIG Welding Evening and learn the basics of TIG welding and what the machines can do. We will progress from Mild Steel through to Aluminium. There is space for two persons and tickets cost £80.00 each.

BOOK - Introduction to TIG Welding

Alternatively, we can arrange a Private Welding Class to cover all things about welding aluminium. Our minimum booking is 3 hours and we charge £40.00 per hour. All the materials and equipment is included. If you have your own machine and want to bring it along we can help with the set up.

BOOK - Private Welding Lesson

How do you finish Aluminium:

There are a number of different finishing methods open to you when working with Aluminium. Some are unique to the material others more generic to finishing metals or alloys. Aluminium is generally used for its resistants to corrosion so it is left in a raw state. However, sometimes people are after a more decorative finish. Below are some ways you can finish aluminium.

Mechanical or milled finishing (Raw Material) - This is a simple and fairly basic finish which is perfect for quicker production and items that are not for show. You simply leave the material as it is. You can provide it with a more brushed look through employing the use of different consumables. We have discuss the suitable options in our other blog post. It may have a duller appearance and a slight white ‘rust’ effect, although it can easily be polished, buffed or blasted to create a smoother finish.

Anodised finishing - The most widely used type of finishing, an anodised finish is created by thickening the oxide layer on the metal to create an extremely durable, corrosion, UV and wear-resistant finish which is ideal for outdoor applications. The thicker the layer of oxidation, the more durable the finished product. This is created by washing, rinsing and then chemically treating the aluminium before the anodising takes place. The finish can be clear or coloured, although the colour range is limited. The benefits of anodised finish are that it is cost-effective in the long run, as it is extremely durable. It is fade-resistant and environmentally sustainable.

Powder Coating - Essentially this is a finish created by covering the aluminium with powder paint that is then melted onto the material by placing the object into a oven. There is a broader range of colour available using this method. Most people use the RAL Classic Colour Chart. Powder Coating is great for creating a wow-finish but can sometimes be expensive.

Thank you for reading. We hope this blog post has helped demystify welding and using Aluminium in your projects. If you want to know more please join one of our courses or get in touch.

Research and content for this blog was Written by Peter Gray. A Design Student and soon graduate from University of Plymouth. During internship spring scheme at The Weld Space.

Peter is interested in all aspects of design with a particular passion for furniture and functional objects. Find out what he creates on his Instagram: @peter_gray_creative